If you are bringing commodities into or out of your facility and using a truck scale, here are a couple of ways to be sure you get the most accurate profits from each transaction.

Your scale should be tested and inspected by a certified scale company every 6 months, at the minimum

In addition to having a scale technician come out and put weights on your scale, the technician you hire should do an inspection around the scale to check for obvious binds or build up of debris and loose rock guards. And if your scale is in a pit, the tech should go in the pit (after the proper entry permits are obtained) and inspect for worn parts and build up. If the company you have testing your scale only comes out and puts weights on it, gives you a report and drives away, you have not had a true test and inspection.

Be proactive not reactive

If you have an older mechanical truck scale that is getting worn and not repeating weight, you may need an overhaul. In order for the technician to give you an accurate idea of how your scale is operating, have the scale jacked up, cleaned and greased, then he can tell you if you need to be budgeting for any major repairs.

Update equipment

If you have an indicator that has been in use for 20 plus years, does not have filtering for outside elements, the key pad is worn, broken or the display is dim, it would be well worth the investment to update your equipment rather than give away your commodities.

In conclusion, your industrial scale is your cash register, plan and simple. Everything you buy or sell off of your scale needs to be the most accurate weight possible to ensure your profits, so make sure that your scale is tested in accordance to weights and measures guidelines. If you take care of your scale by being proactive, you will never be robbed on any profits.

Related Articles

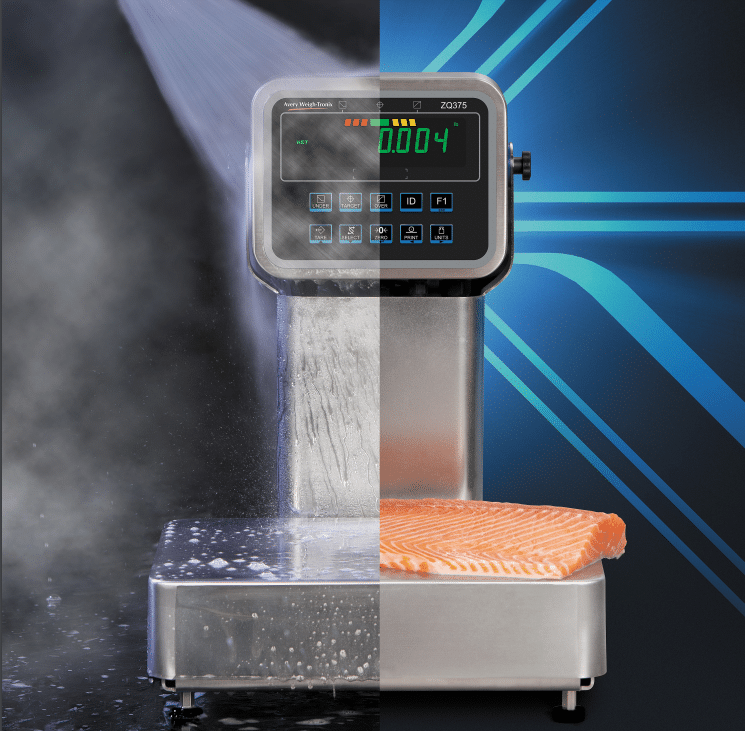

Overcoming Washdown Challenges in Production

1. Water Ingress High-pressure, high-temperature washdowns are a necessity in maintaining stringent hygiene standards, yet they pose a significant threat to sensitive equipment. Water ingress can damage internal components and result in extended downtime. The [...]

Why Hygienic Weighing Solutions Are Essential in the Food Industry

Food safety is the cornerstone of consumer trust, and in today’s competitive food industry, maintaining impeccable hygiene standards is more critical than ever. For decades, RMH Systems has specialized in industrial scale solutions, partnering with [...]

Maximizing Efficiency with Avery Weigh-Tronix ZQ375 Checkweighers

In manufacturing, maintaining efficiency and accuracy is crucial for staying competitive and meeting customer expectations. One effective way to ensure consistent product throughput is by using checkweighers like the Avery Weigh-Tronix ZQ375. These machines not [...]