A shortage in skilled workers threatens the future of manufacturing in the U.S. The boomers retiring, lack of vocational programs, stagnant wages, competitive marketplaces, and uncertainty with the election are just a few of the items impacting our labor force. This will be an ongoing issue we tackle for the foreseeable future. In the meantime, there is “something” punching the clock, and it never punches out. Robots. A new report suggests the global materials handling collaborative robots market is expected to undergo “phenomenal growth” as industrial manufacturers deploy them to assist the lack of human workforce.

The outlook for both the packaging and materials handling industries is bright. The PMMI’s (The Association for Packaging and Processing Technologies) “2016 State of the Industry Report” forecasts U.S. shipments of packaging machinery to reach $8.5 billion in 2020 at a CAGR of 2.5%. Research and Markets has released a similar report forecasting a 3.47% CAGR. The Conveyor Equipment Manufacturers Association (CEMA) has reported an increase of 99% in the booked orders of August and September of 2016 as compared to the same months in 2015. They expect this trend to continue. But as the industries experience consistent growth and expansion, many companies are running into the same issue: labor shortages.

Retirement, Workforce Challenges Drive Need

According to Modern Materials Handling, the need is driven primarily by the rate of retirement and reduction of new workers. About 2.7 million workers will retire from the manufacturing industry in the next decade or so. Finding a suitable number of skilled workers to replace that 2.7 million is a daunting task. Manufacturing has a tarnished reputation with millennials, and there aren’t enough vocational or Associate’s programs out there to market to young adults. “Despite slower growth, finding talent is still one of the greatest challenges facing manufacturing today. Machinists, workers, and assemblers are among the top occupations in demand, while workers with skilled trade backgrounds such as welding and machining are also high in demand,” said Sara Staggs, Director of Divisional Operations at Aerotek. There are an estimated 78,000+ job openings in the aforementioned skill sets across the U.S.

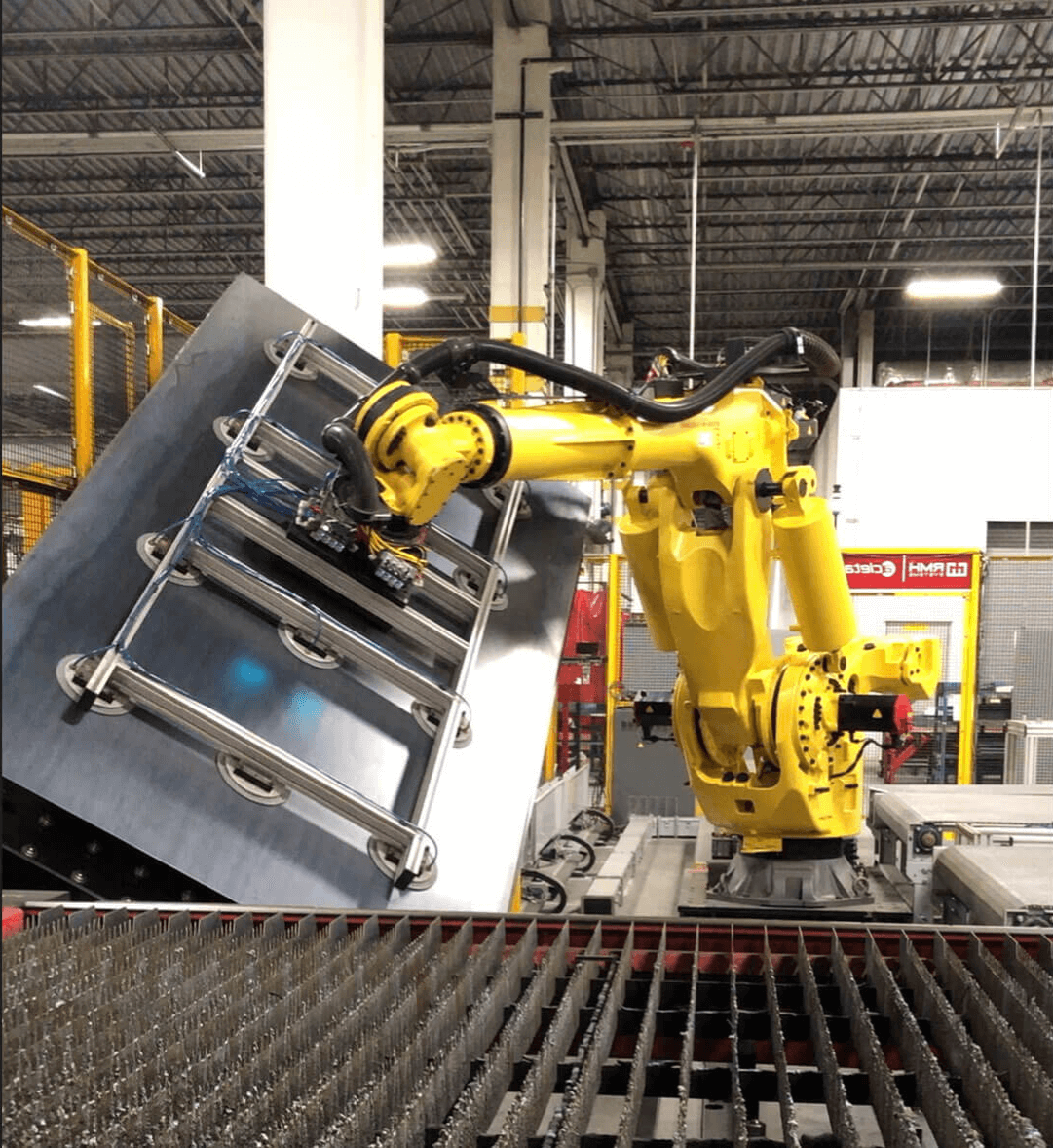

Automation is a hot topic in this industry. “We need to find efficiencies”…”We need increased throughput”…”We need to streamline operations”…”We need to think about automation”…Sound familiar? Many folks want to gain results while they “think” about automation. As we face a growing labor shortage, there is no more time to think about automation. Robotics increase speed, increase output, and decrease stoppage time. No breaks, no injuries, and no open positions. This doesn’t mean we replace the labor force we currently have, this means we can re-deploy the labor force to more meaningful positions.

According to “Global Material Handling Cobots Market by End-User Analysis and Outlook”, collaborative robots are smaller, more affordable, user-friendly, and flexible than traditional industrial robotics and are especially suited and appealing to small- and medium-sized enterprises for industrial manufacturing. Robots designed for materials handling represent the most prevalent application for collaborative robots.

RMH Systems is an integrator of robotic applications. What separates us from our competition is that we can not only integrate the robots, we can integrate the conveyor and packaging lines that operate with the robots. Please give us a call, so we can develop the appropriate solution for your team, and eliminate any stress associated with labor shortages.