Related Articles

New Budget Law Accelerates Payback for Manufacturers: What You Need to Know

The newly signed One Big Beautiful Bill Act (OBBBA) makes it easier — and faster — for U.S. manufacturers to invest in automation, equipment, and even production buildings. For RMH Systems customers this means shorter [...]

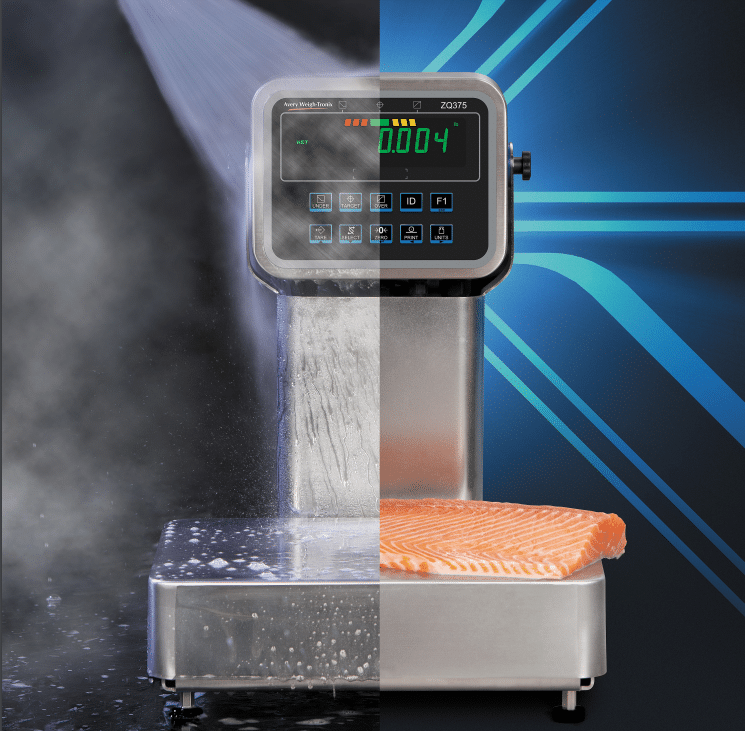

Overcoming Washdown Challenges in Production

1. Water Ingress High-pressure, high-temperature washdowns are a necessity in maintaining stringent hygiene standards, yet they pose a significant threat to sensitive equipment. Water ingress can damage internal components and result in extended downtime. The [...]

Why Hygienic Weighing Solutions Are Essential in the Food Industry

Food safety is the cornerstone of consumer trust, and in today’s competitive food industry, maintaining impeccable hygiene standards is more critical than ever. For decades, RMH Systems has specialized in industrial scale solutions, partnering with [...]