Today’s agrochemical industry is under pressure to keep up with ever-increasing global production demands. Introducing or adding new automation components to your agricultural chemical liquid filling line can help you meet those goals, but optimizing production requires thoughtful consideration, planning and execution

Let’s explore the different aspects of automating your liquid filling process so you can make informed decisions that fit into your long-term business strategy.

1. Fill Line Layout

When companies upgrade their liquid fill lines, they’re typically doing so in an existing building that has constraints. Having the right layout along with the right equipment can make or break the success of your new line.

If equipment doesn’t work with that layout, you may end up limiting your rate or even having the project not work entirely. This can end up costing you directly through change orders or indirectly over time through loss of throughput.

2. Fill Line Configuration

It’s recommended to plan your line to either run one product quickly or run several products at a lower rate. Or you may even want to use two separate fillers on the same line to avoid changeovers that eat up valuable time.

With whichever configuration works best for your operations, it’s also advised to know your packaging format and other key details such as viscosity and seals. This will be helpful information when you’re finding an industrial automation system integrator to partner with on your project.

3. Liquid Fill Product

Many decisions are determined by your liquid fill product. For example:

- Temperature—Is the product cold, room temperature or hot during the bottling process, which may cause the container to expand?

- Viscosity—Is the product a thicker viscosity? Does it foam?

- Packaging type—Are you using plastic containers, jerry cans, pails, drums or something else? How will this packaging be orientated as it goes into the chemical liquid filling machine?

- Giveaway—Is it important to reduce giveaway as much as possible due to the product being expensive? Or is increased throughput more important since the product is inexpensive?

4. End-of-Line Packaging

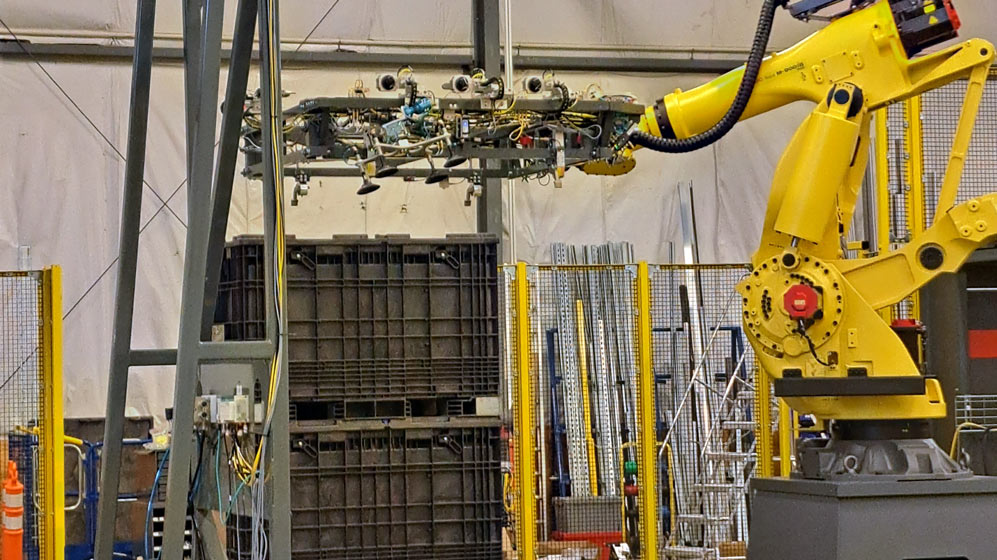

Automating the end of your line is just important as the beginning of it. Automation opportunities for end-of-line packaging includes product labeling, product coding and marking, case forming and sealing, case packing, robotic palletizing, and more.

Here are just a few benefits to adding industrial automated packaging systems to your operations:

- Efficiency and productivity: Automation streamlines the packaging process, leading to increased efficiency and productivity. Automated systems can handle large volumes of liquid ag chemicals with precision and speed, reducing manual labor and minimizing errors.

- Safety: The implementation of automated fill lines in the chemical industry significantly enhances safety standards. By minimizing manual intervention, the risk of human error and potential exposure to hazardous substances is greatly reduced. It not only protects workers but also contributes to environmental preservation by preventing the release of harmful chemicals into the surroundings.

- Scalability: As demand for liquid ag chemicals increases, automation allows for easy scalability. Automated systems can handle larger production volumes without compromising speed or accuracy, meeting market demands efficiently.

- Traceability and documentation: Automated packaging systems integrate with traceability and documentation software. This enables accurate recording of batch numbers, expiration dates and other vital information, making it easier to track products throughout the supply chain and comply with regulatory requirements.

- Cost savings: While initial investment in automation can be significant, the long-term cost savings are substantial. Automated systems reduce labor costs, minimize material waste and optimize production efficiency, leading to improved profitability over time.

- Enhanced customer satisfaction: Automated packaging ensures consistent product quality, accurate labeling and reliable packaging integrity. This leads to enhanced customer satisfaction as they receive products that meet their expectations consistently.

5. Palletizing

Cases may be 50 to 60 pounds once packed, which means you need a safe and efficient way to palletize them. Some companies may use a Gorbel Easy Arm lifting device to palletize, but this requires a human operator.

With the ongoing manufacturing labor shortage showing no signs of easing, palletizing robots help you maximize your employees by moving them from manual labor task to another assignment that requires human oversight, like running a line.

If you’re thinking about adding palletizing robots to your operations, you’ll also need to consider programming and controls integration, appropriate end-of-arm tooling, scalabilty, and training, and maintenance and support.These important factors all go into ensuring you meet your desired production rates as you grow.

6. Choosing an Industrial Automation System Integrator

It’s one thing to be able to select the right equipment from multiple manufacturers for your ag chem liquid fill line. It’s another to make it work together seamlessly. That’s where your industrial automation system integrator comes in.

Working with an experienced integrator, who offers turn-key solutions all under one roof, like RMH Systems ensures:

- Turnkey solutions customized for your needs. With more than a decade of experience in liquid filling, our experienced team knows what works and what doesn’t. From design to installation, we deliver turnkey material handling equipment that’s ready to work for you.

- Cost savings. Our strong vendor relationships mean you’ll receive the right solution at the right price. Your return on investment is both our goal and our specialty.

- Time savings. You’ll work with a fully in-house team instead of multiple vendors, which translates to shorter project implementation time, and a more customized approach to your systemWe’re proud to be the only integrator in the country offering a complete line of automated material handling systems, packaging, robotics and service teams.

- Trusted results. We’ve assisted businesses of all sizes for more than eight years. Our sales, engineering and automation experts have built a reputation of reliability, integrity, ingenuity and success.

Ready to learn more about how automating your ag chem liquid fill line can help you work better, more safely and more efficiently? Request a free consultation today!