If you’re a manufacturer struggling to increase throughout while feeling the pinch of a labor shortage, material handling automation can be an invaluable solution.

You may be wondering: Where do I start? What kind of technology is available to help me automate my processes? What if my line is partially automated but has room for improvement?

We understand your challenges and have compiled this guide to material handling automation for manufacturers so you can quickly identify areas for improvement in your production line and determine which solutions – both investment-wise and personnel-wise – are right for you.

Let’s review some of the top pieces of equipment to consider adding to your line.

Palletizing Solutions

A highly productive production line is crucial to your business’s success. This is why investing in palletizing automation is a wise decision for any manufacturer.

Palletizing Robots

Investing in palletizing robots allows you to make the most of your workers by taking them off repetitive and potentially dangerous tasks.

A robotic palletizer can work much more quickly and efficiently on a 24/7/365 schedule, if your lines allow for it. Here are just a few more benefits they offer:

- Increases productivity by up to 1,900 palletizing cycles per hour.

- Handles more than 300 pounds and finished loads of more than 4,000 pounds.

- Rewards you with consistent stack patterns and less jarring to products, which reduces damage and waste.

- Reduces the risk of lifting injuries.

- Customizable to your operations.

Conveyor Solutions

Moving product quickly is key to helping you fulfill orders faster and increase customer satisfaction.

Heavy-Duty and Industrial Conveyor Systems

Heavy-duty conveyor systems handle substantial loads, making them ideal for transporting large, heavy materials or products across the manufacturing floor. They’re also built to withstand harsh conditions, such as dirty, hot or refrigerated. This ensures longevity and reduced maintenance costs.

These industrial conveyor systems can help you:

- Reduce manual labor

- Minimize errors

- Increase throughput

- Improve overall workflow

Lifting Solutions

Relying on forklifts or manual labor to transport heavy or bulky goods throughout a warehouse can be both inefficient and risky, not to mention it consumes a significant amount of precious floor space. Learn about smarter and safer automated lifting solutions.

Overhead Cranes

An overhead crane is a vital tool in any manufacturing facility because it streamlines operations and increases efficiency while keeping workers safe. They can be used in various stages of the manufacturing process, from handling raw materials to moving finished products.

Jib Cranes

A jib crane is a type of overhead crane favored by manufacturers for handling loads under 5 tons. Here are just a few benefits of adding one to your operations:

- Cost-effective—Since jib cranes aren’t mounted on the ceiling, they tend to cost less than top-running or underhung cranes.

- Relocatable to suit a changing or growing line—Because jib cranes aren’t permanently mounted, you can easily move them as your production line changes or grows.

- Handles a variety of materials—Jib cranes can transport heavy sheets of steel, wood or glass, or move smaller parts across assembly lines.

Intelligent Lifting Devices

Intelligent lifting devices with vacuum lifting capabilities are revolutionizing the way materials are handled in the manufacturing industry. Here are a few reasons why you should consider adding them to your production line:

- Powerful and efficient solution for lifting and moving a wide variety of items, from metal sheets and plastic parts to finished products.

- Contributes to worker safety and ergonomics by taking over the physically demanding task of lifting and moving heavy materials.

- Ensures a secure grip on loads, which enhances safety and prevents damage to materials being handled.

If you’re in a setting that requires accuracy and efficiency, intelligent lifting devices like the Gorbel G-Force are a great fit. The G-Force provides precise control and smooth operation thanks to an industrial processor-controlled servo drive system and load-sensing feedback.

Ergonomic Solutions

Work injuries are all too common, and too preventable to allow. Ergonomic devices protect workers while keeping your process efficient.

Industrial Ergonomic Equipment

The right industrial ergonomic equipment helps your workers perform tasks more comfortably, safely and efficiently. Here are just a few of the solutions favored by manufacturers:

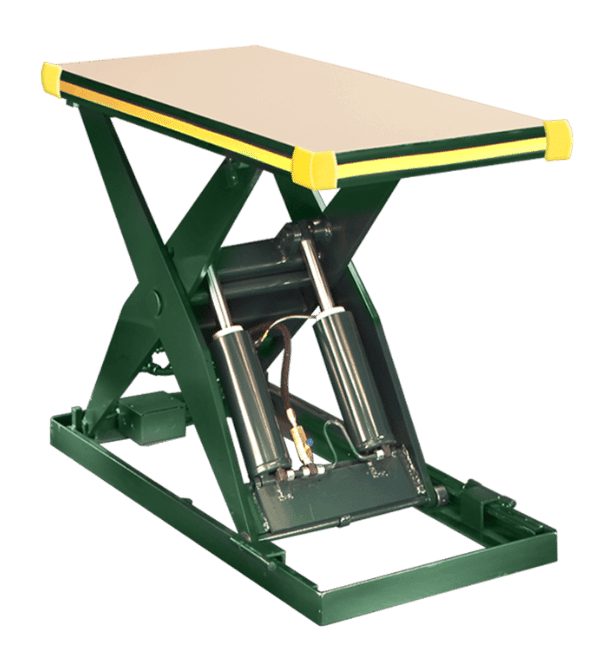

- Lift tables—Raise or lower materials and pallets to an ideal working height.

- High cycle lifts—Ideal for automated machine feeding or off-loading applications.

- Freight lifts—Transfer materials up or down to optimize space, stability, safety and efficiency.

- Tilt tables—Tilts materials to the appropriate angle, removing the need for hoisting equipment. Ideal for welding, fitting components or loading raw materials.

- Upenders—Used for pallet or coil upending or placing product in the correct position for assembly.

- Adjustable work benches and workstations—Helps employees work efficiently and safely in assembly operations.

Partner with RMH for Your Next Material Handling Automation Project

For more than 80 years, RMH Systems has specialized in helping manufacturers of all sizes grow through automation. Whether you’re a small, rural manufacturer starting to automate your processes or a large, well-known brand needing integration with an existing system, our team of turnkey integration experts handles it all. Request a free consultation today to learn how we can help your team work more safely and efficiently.