Biomedical companies were pushed to peak performance during the COVID-19 outbreak and importance of the biomedical field was put on full display. The surge in demand drove the need to produce at higher-than-normal rates. While fortunately the pandemic is behind us, biomedical companies continue to look for ways to address labor concerns and keep up with increased demand for products that keep us all healthy. Here are four ways material handling can help biomedical manufacturers keep up with increased demand.

Intelligent Lifting Equipment

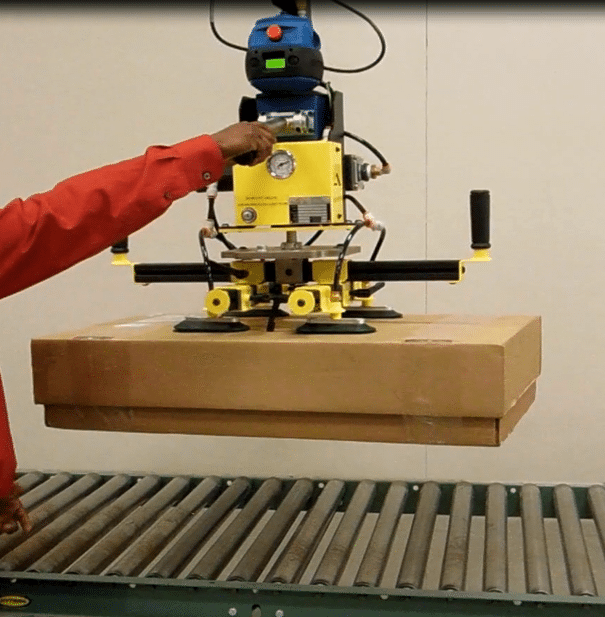

Intelligent lifting equipment, like vacuum lifters and ergonomic end-of-arm tooling, can reduce the force needed to complete lifting tasks by up to 78%1. Decreasing the energy needed to complete tasks can also decrease the number of workplace injuries sustained while carrying out tasks on regular lifting equipment. Additionally, companies that employ intelligent lifting equipment have also seen their productivity jump up as far as 75%1. This added productivity can be attributed to the intuitiveness of intelligent lifting equipment, and the ease of use to complete tasks. Intelligent lifting equipment can help provide the bump necessary to stay ahead of the curve by minimizing workplace injuries and maximizing product lifting productivity.

The Gorbel Easy Arm & G-force is a great example of intelligent lifting equipment in action.

Utilizing intelligent lifting equipment to move around boxes of finished biomedical products ensures a significantly decreased risk of damaging loads. Companies that employ intelligent lifting equipment in the end of line processes experience 3.3X less damage to loads compared to companies using generic lifting processes1. The products that biomedical companies produce are fragile and widely depended on, so ensuring that the products leave the building undamaged is a necessity.

Vertical Lift Modules

Companies can save 90% of the floor space that was previously occupied2 by replacing traditional storage methods with a Vertical Lift Module. Vertical lift modules, or VLM’s, allow companies to store a large inventory that can be quickly accessed, increasing the performance of their storage and retrieval processes. VLM’s make storage smarter. Companies can optimize picking and allow batch order processing with computer-driven storage activities. Companies that integrate VLM’s into their storage process can see their productivity increase by up to 200-400%3. As industry regulations call for increased focus on quality assurance, VLM’s are designed to keep products in a secure and clean environment. The VLM is fully enclosed with an automatic door that prevents goods from being damaged and minimizes outside exposure.

VLM’s also provide biomedical companies with real-time inventory management which can improve inventory control and stay on top of replenishing products. By keeping companies aware of their product levels, VLM’s can help companies make informed inventory decisions and drop-down costs.

Arguably the VLM’s most relevant advantage for the biomedical industry is the level of safety and security they provide. VLM’s provide multiple layers of security for companies starting with their self-weighing capabilities. By managing tray and unit weights, VLM’s are able to ensure the right number of products are in the correct places. Additionally, VLM’s are completely enclosed and require log-on and log-off passwords in order to operate them. This helps companies keep track of who is operating the VLM, what they are picking, and ensuring that there is no product interaction outside of outlined procedures.

Custom Conveyor Systems with Built-in Scales

The biomedical industry has some of the most stringent regulations of any industry. Custom conveyor systems can be built specifically to adhere to these regulations. Custom conveyors can be constructed of stainless steel and open completely for washdown to ensure the clean environment necessary for the production of biomedical supplies. Having a custom warehouse conveyor system that is flexible, can meet demand, and can easily adapt to changing needs is important to reduce the chances of production shutdowns and delays.

Conveyor systems with built-in scales can provide an added layer of productivity to biomedical companies. The regulations present in the biomedical industry require extremely precise weighing processes in order to meet their necessary standards. By integrating a scale into a custom conveyor system, products can be weighed while conveyed. By combining these two processes, conveying and weighing, biomedical companies can save space in their building and time in their production all while staying up to code.

Mezzanines/Offices – Clean Rooms

Mezzanines offer companies the ability to increase their usable space without the need for a full building expansion. Mezzanines can save companies $15 per square foot4, which can add up pretty quickly. Implementing a mezzanine is a cost-effective, efficient, and customizable option for companies that are in need of more space in their building. Oftentimes, mezzanines can be constructed without needing to shut down any production processes.

Biomedical companies across the country are ramping up production. This increase in production requires expanded manufacturing, which requires additional square footage. Mezzanines allow companies to effectively double5 the amount of usable space in a building to help meet the increased demand. And thanks to the customizable nature of mezzanines, these new work areas can be built to meet the regulations of a biomedical ‘clean room’.

The biomedical industry is going through an unprecedented level of increased demand right now. Being able to continually meet these constantly increasing demands is crucial in keeping people healthy. RMH Systems provides solutions that can help biomedical companies stay productive and efficient even in these difficult times. If you want to integrate material handling solutions into your biomedical production fill out our contact form here.

1https://www.assemblymag.com/ext/resources/images/2020/Gorbel/intelligent-lifting/intelligent-lifting-ergo-study.pdf

2https://www.modula.us/news/why-expand-your-warehouse-if-you-dont-have-to-choose-modula-vertical-lift-module.html

3https://www.southwestsolutions.com/benefits-of-a-vertical-lift-module-for-warehouse-productivity-space-savings

4https://mezzaninedistributors.com/resources/mezzanine-in-a-new-building/

5https://www.mskcanada.com/en/blog/the-advantages-and-disadvantages-of-installing-an-industrial-mezzanine-compared-to-expanding-a-warehouse