RMH Systems is an industrial automation system integrator, but what exactly does that mean? What are automated industrial systems? Most importantly, why is it important to find a good integrator partner?

What is an industrial automation system?

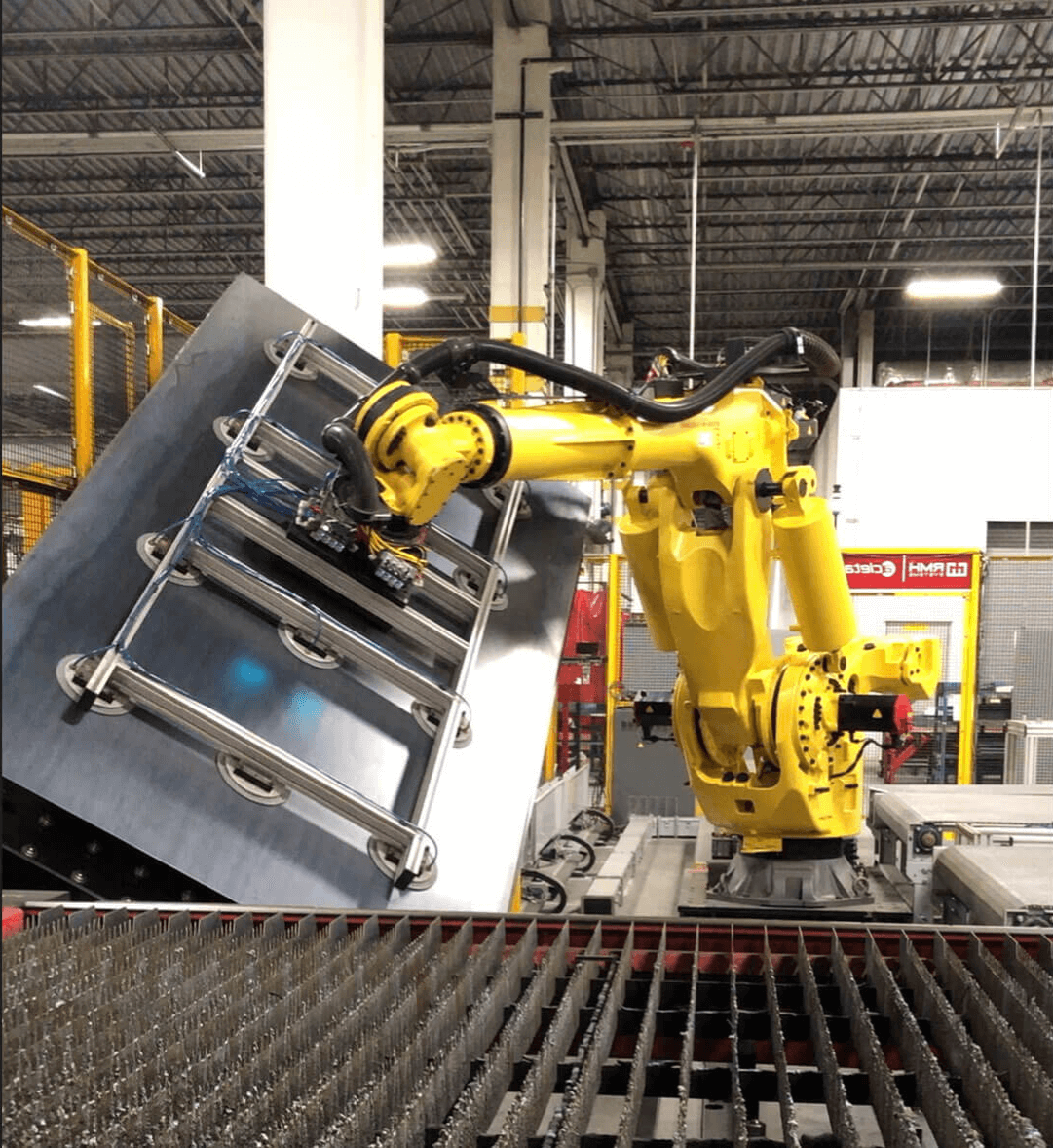

Industrial systems is a broad spectrum term that includes simple conveyor systems to complicated robotics system integration all based around improving a facility and worker’s performance and production. Companies that truly employ automated equipment incorporate consistent precision, accuracy, speed, and traceability into their industrial processes.

Why are companies looking at industrial automation systems?

One of the primary reasons is the lack of a labor force. Many industrial companies are experiencing a frontline labor shortage. Companies are turning to industrial automation to reduce their dependence on temporary labor and maintain consistent production levels with fewer people.

Industrial automation improves the working environment for frontline workers. Automated equipment like industrial robots removes employees from processes that are dirty or dangerous which mitigates injury risk. Employees are repurposed to more value-added complex roles and responsibilities.

Finally, industrial automation systems improve the speed, efficiency, reliability, and quality of production. Automated systems don’t take time off, don’t get injured, and deliver a level of accuracy that a human is incapable of. Automated equipment platforms ensure that production runs at peak potential and shipments can remain timely throughout the work cycle.

What are some signs that I may need industrial automation?

- Multiple workplace injuries due to repetitive motion

- A large number of products returned due to damage or quality reasons

- Have employees performing non-value-added tasks like manually weighing product or label application

- Having trouble finding enough/qualified employees

- Repetitive, heavy, and dangerous tasks

Why is choosing the right integrator partner so important?

- Efficiency – integrators that house multiple divisions (material handling, packaging, robotics) under one roof provide one point of contact on projects. Companies no longer need to subcontract 3 or 4 different companies to implement a turnkey system.

- Expertise – the right integrator will have decades of engineering and sales experience in-house. In-house engineering is vital because it’s the integration of the various pieces of equipment that is the most difficult (and a good integrator should be able to manage that)

- Experience – you want an integrator that has worked across industries for many years. Your custom project shouldn’t scare and integration partner – it should excite them. There’s always a solution. Many times what an end user thinks they want is different than what they need. A good integrator will steer you to the needed solution based on experience.

- Quality – Your integrator/distributor has chosen relationships with OEMs across the country. Choose a partner that represents industry leaders in automation equipment to ensure that your system is composed of the best machines and products available.

- Choice – the right partner will have options from different manufacturing partners for your project.

Want to learn more about our robotics system integration, or want to find out how it can help you? Fill out this contact form to get in touch with our engineers!

Related Articles

Are Your Packaging and Material Handling Systems Ready for FSMA 204?

Key Takeaways FSMA 204 raises the bar for food traceability, requiring manufacturers to capture and maintain critical data at key points throughout production and distribution. While the regulation is often viewed as a software [...]

5 Year-End Material Handling Problems to Solve Before 2026

Key Takeaways This article explains how solving common year-end material handling challenges—such as unfinished projects, deferred maintenance, inefficient layouts, and delayed automation—can help operations start 2026 with improved safety, efficiency, and ROI. Year-end is [...]

New Budget Law Accelerates Payback for Manufacturers: What You Need to Know

The newly signed One Big Beautiful Bill Act (OBBBA) makes it easier — and faster — for U.S. manufacturers to invest in automation, equipment, and even production buildings. For RMH Systems customers this means shorter [...]