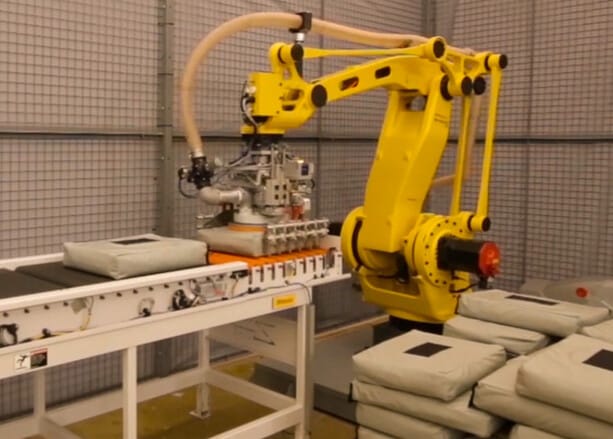

PALLETIZING ROBOTS

Increase Productivity, Lower Operating Costs and Create a Safer Work Environment with Palletizing Robots

Efficiency matters now more than ever. And a highly productive line is key to your success. That’s why palletizing robots are a smart investment for any company that manufactures, handles, distributes, or packages products.

RMH Systems is your single-source partner for industrial robotics. Because we leverage in-house engineering, implementation and aftermarket service expertise, you won’t have to coordinate with multiple vendors. That’s why working with our robotics company is as efficient and seamless as the systems we’ll customize for your company.

For more than 80 years, RMH has been helping companies like you work more safely and efficiently. Contact us today about how our turnkey robotic palletizer solutions can help you work smarter and grow your business, regardless of scale or complexity.

8 Benefits of Robotic Palletizers

Industries Where Robotic Palletizing Systems Are Used

Agriculture

Chemicals

Recycling

Food and Beverage

- Cheese and dairy

- Cold storage

- General production and distribution

- Primary meat and poultry

Medical

- Chemical pharmaceuticals

- Life sciences

- Medical equipment and precision mechanics

Manufacturing and Distribution Centers

- Consumer goods

- E-commerce

- Electrical and electronics

- Textiles and clothing

Materials

- Ceramic mineral products

- Composite

- Construction material, including concrete, brick and pavers

- Glass

- Metal products

- Paper and printing

- Rubber and plastics

- Wood

This is just a sample of the industries where our palletizing robots are used. Don’t see yours listed?

Applications and Configurations for Automatic Palletizers

There is a broad range of applications and configurations where automated palletizer systems can be utilized. In addition to cases, they can be designed to handle most products of varying materials, shapes, sizes and weights. Some of these applications include:

- Plastic carton palletizing

- Bag palletizing

- Beverage palletizing, including cans, glass and plastic bottles

- Corrugated box palletizing, case palletizing and box palletizing

- Drum palletizing for all sizes, including 5, 30 and 55 gallons

- Pail palletizing

- Layer palletizing for freezers, harsh temperatures and environments

- Mixed case palletizing

We offer a wide range of configurations from single pallet to custom system layouts. Ask our engineers for more information about how we can design a solution for your unique needs.

Capabilities of Palletizing Robots

- Handles any material with a stable base. This includes, but is not limited to:

- Bags

- Bales

- Barrels

- Bottles

- Bundles

- Cartons

- Cases

- Jugs

- Parts

- Pails

- Totes

- Trays

- Common palletizing applications pick up more than 300 pounds and handle finished loads of more than 4,000 pounds.

- Completes up to 20 cycles per minute for common palletizing and up to 30 per minute for bags.

- Compatible with harsh environments and temperatures, including blast freezers and refrigeration used in food production. Can be used with freezer boards, which allows airflow during the freezing process, and then palletized into a tighter pattern when freezing is complete.

- Can be integrated with automatic stretch wrapping.

- Vision and scanning capabilities for barcodes and other identifying marks.

- Other capabilities include upstream vision, product labeling, case sealing and forming and sortation.

These are just a few of the capabilities of automatic robot palletizers. Ask our engineers about how we can customize a system that meets your needs.

Our Palletizing Robot Solutions

RMH offers palletizing robot design to meet the unique needs and goals of your business. Learn more about the robotic palletizing solutions we offer.

Robotic Bag Palletizers

Whether your company makes pet food or produces supplies the agricultural, chemical and building industries depend on, robotic bag palletizers handle industrial-sized bags with ease.

Robotic Bottle Palletizers

Using robotic bottle palletizers rewards you with consistency every time. You’ll enjoy a competitive edge on fulfillment speed while reducing damage from crushed, broken or damaged bottles.

Robotic Can Palletizers

Put your employees to better use with robotic can palletizers. They effortlessly handle repetitive and potentially dangerous tasks, like stacking heavy pallets of aluminum or glass cans.

Robotic Case Palletizers

Increase productivity with robotic case palletizers. These systems integrate with other equipment that makes your operation more efficient, including product marking, case forming and sealing and stretch wrapping.

Slip Sheet Dispensers

Completely automate the pallet building process by integrating a slip sheet dispenser. These pneumatic or electrically driven dispensers integrate with the palletizer to provide your slip sheets automatically.

End-of-Arm Tooling (EoAT)

Custom robotic tooling to provide the right solution for your application. Mechanical/pneumatic grippers, suction cups, or vacuum gripping systems.

Conventional Palletizer

Low or high level palletizers. Perfect for applications with limited SKUs or products to be handled. Conventional Palletizers are more economical and easier to troubleshoot.

Pallet Dispensers

Eliminate the manual handling of pallets. Dispensers are an important piece to any palletizing operation – a pallet is always ready. Reduce manual labor, improve productivity, and lengthen the life of your pallet.

Robotic Palletizing Projects Capabilities

More leading manufacturers, producers and companies are choosing RMH as their single-source robotics integration partner. Learn more about the palletizing projects we’ve completed across North America.

Major Food and Beverage Companies

Multiple liquid and dry fill plants across North America

Projects

- Robotic case palletizers

- Robotic bag palletizers

- Robotic barrel palletizers

- Conveyor lines with controls and integration

- Automatic stretch film wrappers

- Fully automatic case sealers

- Print and apply labelers

Environment: Hot and dusty | Cool, damp and wet | Temperature controlled

Major Ag Chemical Producers

Sites in Iowa, Georgia, Missouri and Nebraska

Projects

- Palletizing robots

- Robot depalletizers

- High speed rotary fillers and automatic liquid filling machines

- Automatic case packers

- Fully automatic case sealers

- Automatic stretch film wrappers

- Print and apply labelers

- Controls and integration

Environment: Hot and cold | Dusty

Experts in System Integration

RMH Systems creates solutions that make it even easier for you to automate and grow.

FANUC America Authorized

Our team includes robotics, software, mechanical and electrical engineers. Let us be your FANUC America Authorized Systems Integrators.

Turnkey Supplier

As a turnkey supplier, we provide all the hardware, software and integration engineering you need. We’re here when you need us for local service and software support.

Conveniently Located

We’re conveniently located in the Midwest and work with companies across the country. Our repeat customers include Fortune 50 manufacturing, food, distribution and pharma companies.

Broad Expertise

From system design to robotic controls, end-of-arm tooling and human machine interface programming, our experienced team handles your project in-house. This includes implementation, training and aftermarket service.

Solutions Oriented

As a leading distributor, we have access to many product lines in each of our areas. We can design a custom solution that fits your needs and provide simulations to show functionality and system flow.

Right Size

We’re just the right size to take on large projects without the bureaucracy.

LET’S TALK ABOUT ROBOTICS AUTOMATION

We’ve completed projects of varying sizes across the country. No job is too big or too small for us. Ready to learn more about maximizing your ROI? Speak with one of our engineers today! We’ll help you design a solution that solves problems and meets your goals.