INDUSTRIAL AUTOMATION SYSTEMS: WORTH THE INVESTMENT

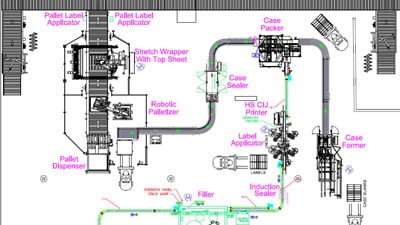

Innovative technology is driving process change in the supply chain. Industrial automation systems are no longer something to consider, they are an absolute necessity to stay competitive and realize growth potential. Every step in the supply chain process requires accuracy, traceability, and speed. We can help your team think through process flow optimization through the design and integration of material handling, packaging, and robotic automation solutions.

Success requires comprehensive engineering to develop and increase efficiencies throughout your warehouse. Our engineering teams in Minnesota, Iowa, Illinois, Nebraska, Kansas City and the surrounding states can help you think through your project. Our experts design innovative solutions to optimize space and automate production. Our engineers design, program, and install robotic cells, automated material handling equipment, and end-of-line packaging systems. Most importantly, our teams have the experience to integrate new equipment into existing systems, and we support our equipment systems after they are installed.

WHY AUTOMATE NOW

Looking for even more reasons you should automate your warehouse? Read our “Complete Guide to the Warehouse of the Future” or discover how distribution center conveyor systems can improve overall efficiency.

We are headquartered in Waukee, Iowa, but we have sales experts throughout the Midwest. We are the Midwest leaders, but we do projects all over the country.

Speak With An Expert

Ryan Pleak

Systems Manager

PHONE: 515.987.7959 MOBILE: 402.319.8456 rpleak@rmhsystems.com

CONTACT US

Fill out the form below to get in touch with our engineers.

Contact RMH Systems

"*" indicates required fields