At RMH Systems, we’re committed to creating solutions that makes it even easier for you to automate and grow. Our industrial robotics team specializes in integrating innovative systems and equipment that make your worksite more efficient and safer.

We don’t make a single part of your industrial robotics system, but we could be the most important part of all. You won’t have to coordinate with multiple vendors when you work with RMH. With our in-house expertise for engineering, implementation and aftermarket service, we’re your one source for seamless industrial robotic automation.

As one of the leading FANUC robot integrators, we’ve completed projects for leading manufacturers, producers and companies across North America. Learn more about the industrial robots we can integrate for manufacturing, packaging and more.

Request a Free Consultation

AUTHORIZED FANUC ROBOT INTEGRATORS

Our team includes robotics, software, mechanical and electrical engineers who are authorized FANUC Robot Integrators. When it comes to robotic systems integration, FANUC is trusted by more companies than anyone else. FANUC’s manufacturing robots are suitable for a wide range of industries, including agriculture, food and beverage and many more. As your robot integrator, RMH is ready to hear about your needs and create a solution that will improve quality, throughout and productivity, giving you the return on investment that you’re looking for.

EXPERTISE TO HANDLE YOUR ROBOTIC SYSTEMS INTEGRATION IN-HOUSE

Our robotics company has the engineering expertise to handle your full project in-house. We simplify the process by being your one go-to source for information, questions and concerns. We’ll implement your entire turnkey system and then provide training and aftermarket service. Learn more about our solutions for industrial robots.

Palletizing Robots

Stack products with palletizing robots that reduce injury and increase efficiency. Mechanical or vacuum end-of-arm tooling options available. View Palletizing Robots >

Robot Depalletizers

Unstack products with robot depalletizers that reduce injury and increase efficiency. Mechanical or vacuum end-of-arm tooling options available. View Robot Depalletizers >

Machine Tending Robots

Cut costs, gain capacity and save time with robotic machine tending, which loads and unloads from your machine tools.

Robotic Laser Cutting

Use less energy and increase production with robotic laser cutting’s pinpoint accuracy and controls.

Material Handling Robots

Effortlessly handle repetitive, tiring and heavy tasks with a material handling robot.

Robot Vision Systems

Increase flexibility and cut automation costs by adding a vision system to your robot.

Robot Work Cells

Optimize and manage your systems with a cell controller custom-built for your needs.

Robotic Sealant Application

Consistently and accurately dispense the sealant products needed in your operation.

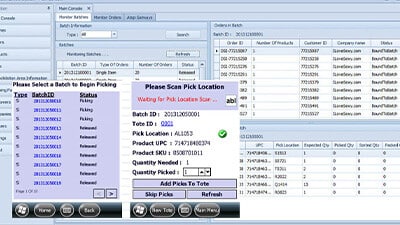

Data Tracking

Precisely manage product data from start to finish through your system. Then store it in a database for future analysis.

Hard Automation

Do the same repetitive task with cost-effective automation for operations that don’t require flexibility.

Assembly Robots

Assemble more quickly and more precisely with robots that move faster than humans.

High-Speed Pick and Place Robots

Accurately and quickly pick and place your low-weight product into shipping cartons.

Welding Robots

Receive consistent, accurate and tireless robotic welding for your manufacturing operation.

LET’S TALK ABOUT ROBOTIC SYSTEMS INTEGRATION

We’ve completed projects of varying sizes across the country. No factory automation job is too big or too small for us. Ready to learn more about maximizing your ROI? Speak with one of our engineers today! We’ll help you design a solution that solves problems and meets your goals.