Experts in System Integration

Material Handling

Make the most of your space and optimize throughput with custom material handling automation for conveying, lifting and racking.

Packaging

Streamline your end-of-line packaging process with automated systems that package, label, mark and pack products. Enjoy improved customer satisfaction through faster, more accurate and on-time shipments.

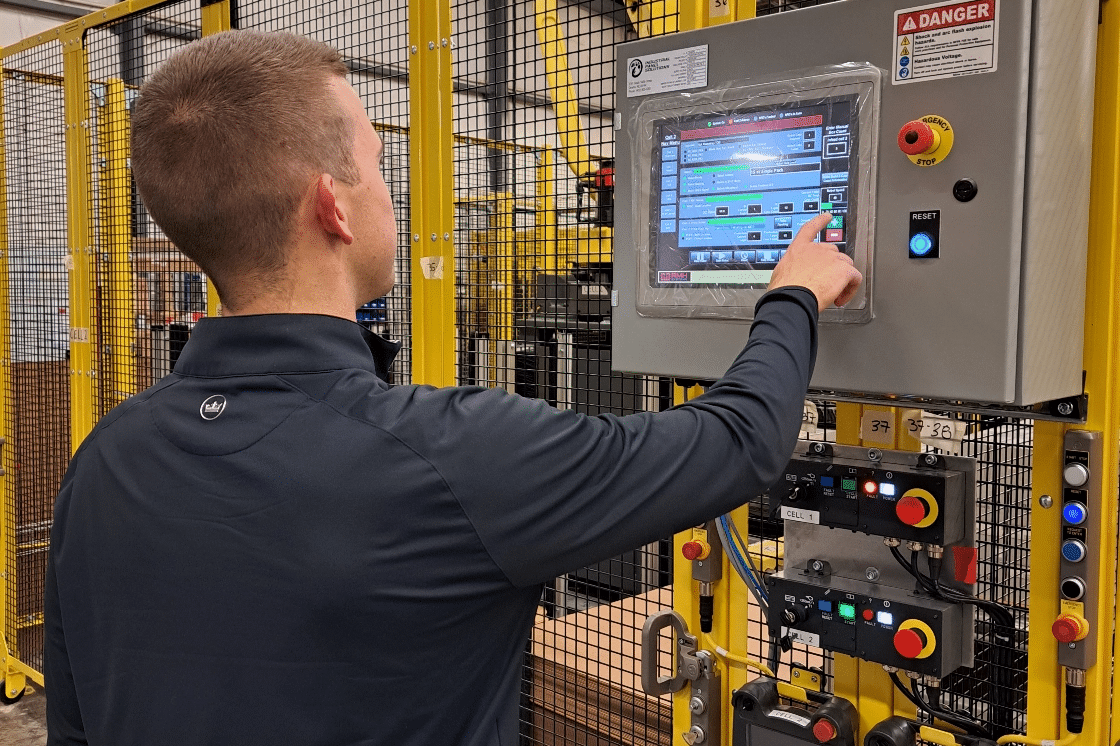

Systems Engineering

Keep your line running consistently, your employees safe and your production steady with capacity to grow. We specialize in industrial automation for manufacturers and automated order fulfillment systems for warehouses. Our services include systems engineering, robotics, palletizing, packaging automation and more.

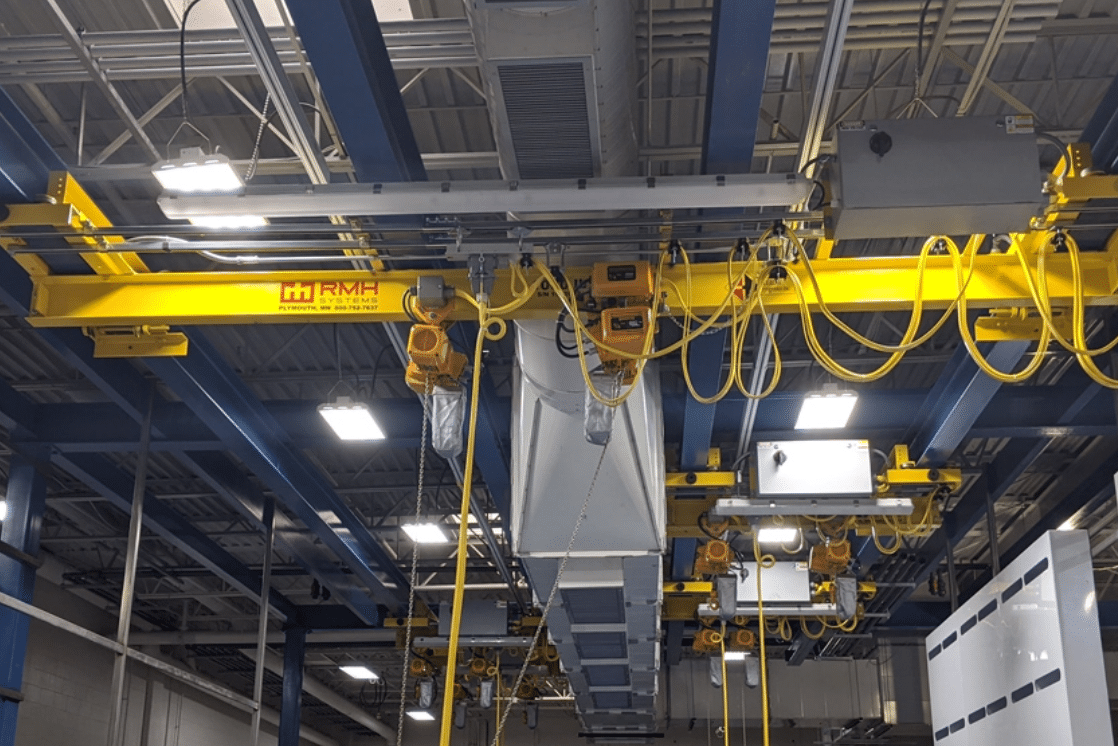

Cranes

Easily lift, lower or suspend heavy materials with heavy-duty overhead cranes that improve efficiency and safety.

Customer Testimonials

“RMH is always up-to-date on new innovative technology as it relates to product handling & packaging. They’ve always provided excellent service, and thoughtful advice. I have found them to be extremely detail-oriented, and they do a great job communicating throughout the lifeline of a project.”

Trevor Caviness, Caviness Beef Packers, Ltd.

“RMH Systems helped lead me in the right direction to purchase appropriately sized equipment that matched our needs and our budget, which ensured a greater return on our investment.”

Aaron Kahl, Smitty Bee Honey